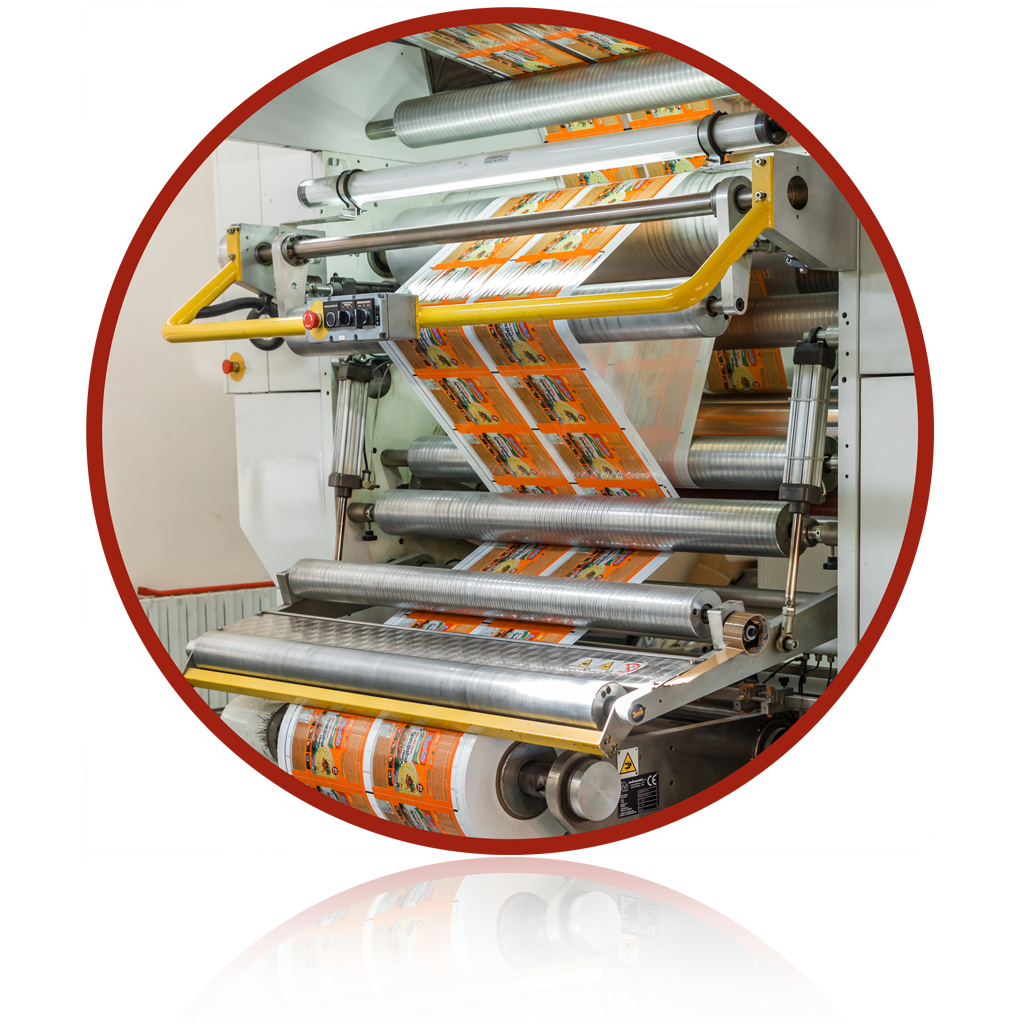

The strategic commitment to cover the segments of the target markets with the highest quality of printing of packaging materials has influenced our decision to select the equipment with the central cylinder, in the design of printing technology, which is most suitable for printing thin films, and to accept the required graphic design solutions with a printing capacity of up to ten colors.

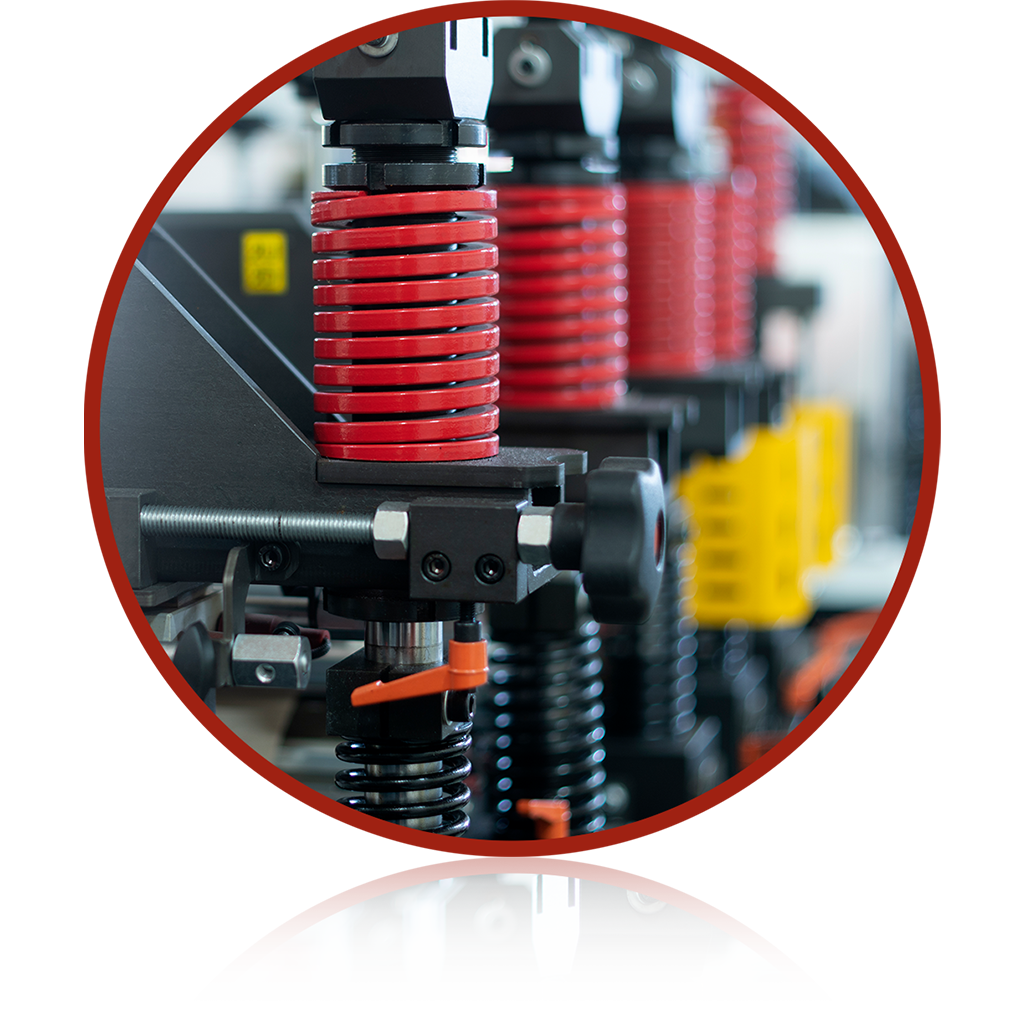

The central place in the technological process of printing take three flexo machines with a maximum width of the printing material of 1500 mm. All three machines are the latest generation of flexo technology, highly efficient and productive, equipped with 100% print inspection systems, with reduced CO2 emissions and efficient washing and stuffing systems.

Today, we are able to offer our customers the decorative techniques of partial lacquering with matt and glossy lacquers, as well as the texturization of the contact surface of the packaging with the “paper touch” effect.

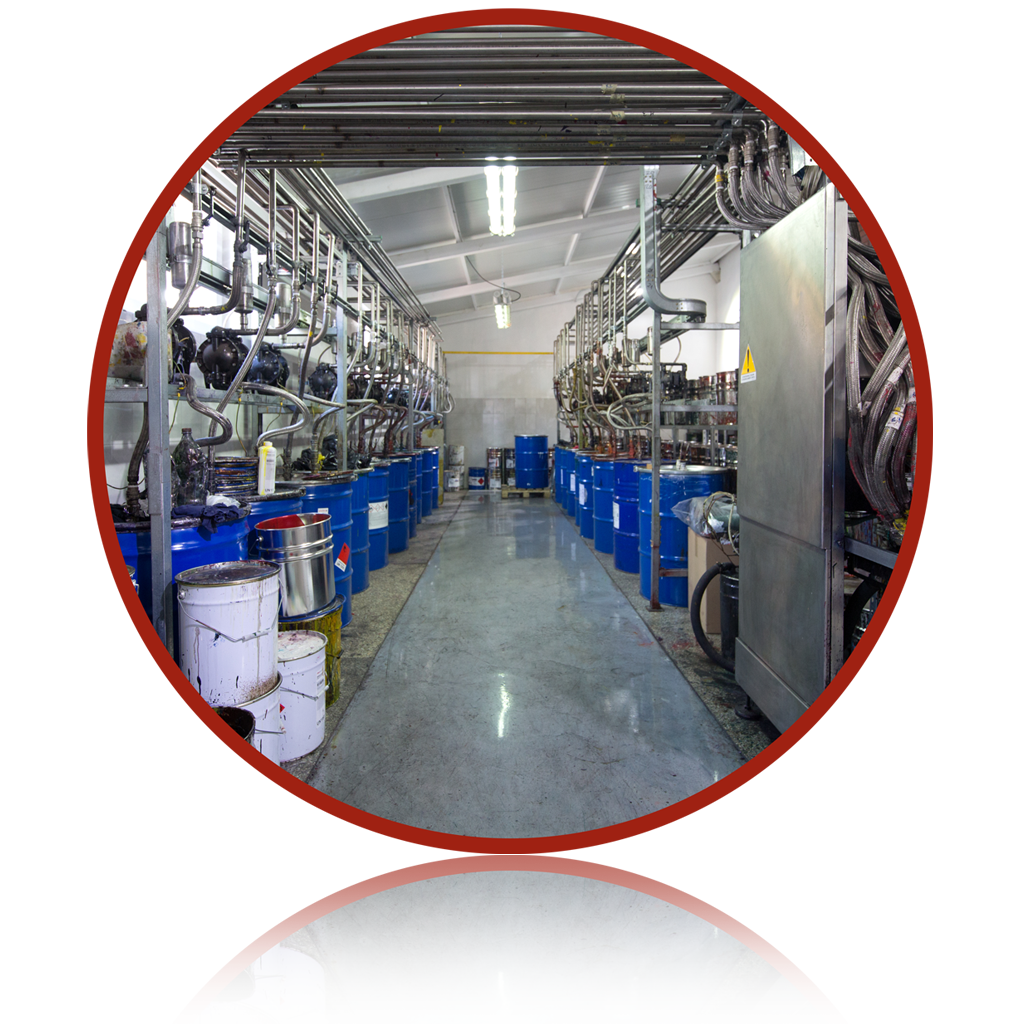

Color Management

Ink maker system for computer color tinting

Inkmaker automatic dispersion system for the production of printing colors, directly linked to the X-Rite Ink Formulation software for precise creation of shades, in combination with the measuring device X-Rite Exact provides fast and precise creation of shades according to the client’s request.

Esko Kaleidoscope is a superior tool from the Esko Artwork family that specializes in profiling monitors, printing machines, printers and their mutual color space matching, with the aim of providing a realistic presentation of print quality options through a proofing system.

Thanks to this color management system, we provide repeatability, predictability and consistency at every stage of the production process.

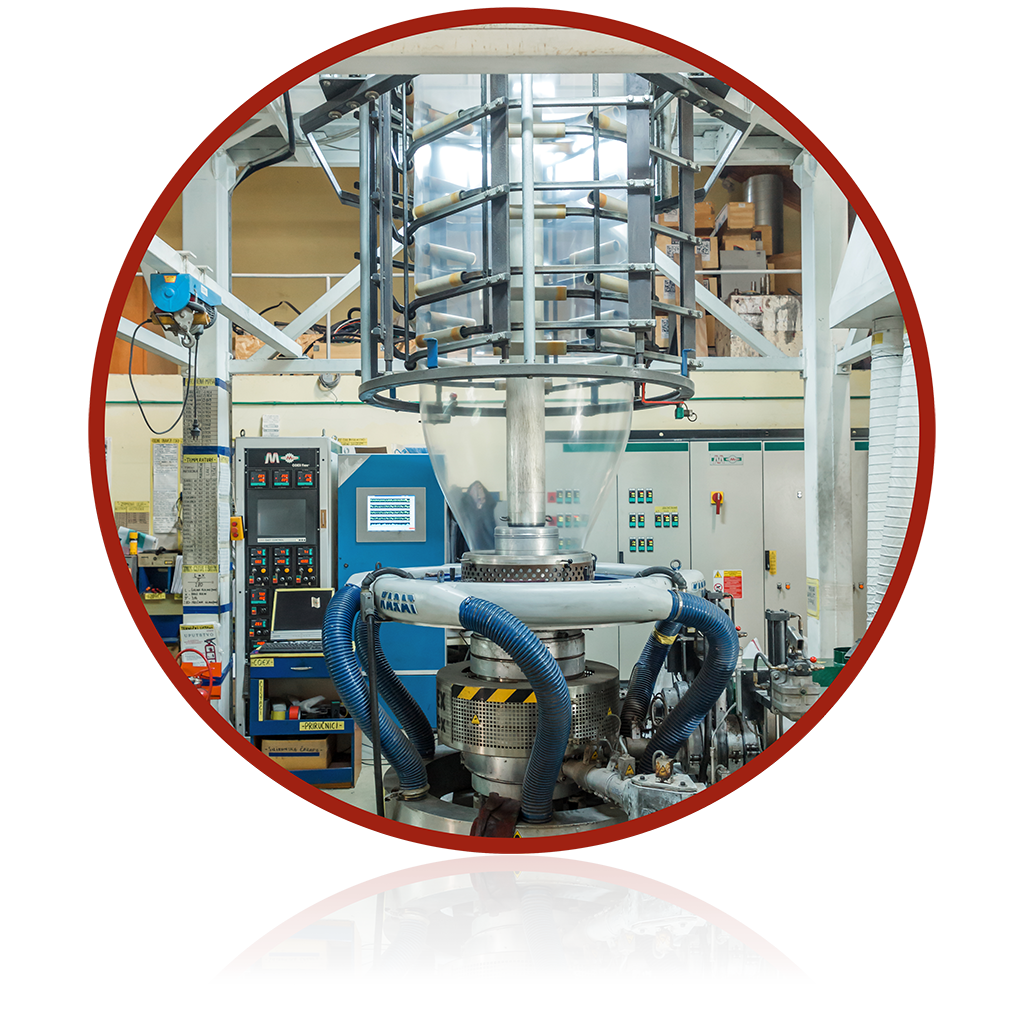

Co-extrusion

The line for co-extrusion of polyethylene film

Considering the specific and different technological and technical requirements of the packaging materials used in the markets that we have targeted, and in view of the need to fully control the technical characteristics of the material, Comex realized the investment of the equipment for the co-extrusion of polyethylene film with a total capacity of 2000t per year. The polyethylene film coextrusion line is of Italian production and consists of a three-layer co-extruder and PE film recycling equipment. In its composition, the co-extrusion line contains the electronic stability control of the film producer “K-design”, which contributes to the high-quality characteristics of the polyethylene film obtained.

On this line, it is possible to obtain multi-layered polyethylene films with adequate properties for packaging detergents, frozen products, milk, paper and cotton confectionery (toilet paper, tissues, pads) as well as various grain and powder products. It is also possible to provide ideal film properties for special packaging requirements such as vacuuming, pasteurization, high speed packaging, etc.

The polyethylene produced is of ideal mechanical properties when it comes to the use of a film for printing and lamination, and can be obtained in thicknesses ranging between 25 and 200 microns, with a maximum width of 1.6 m, covering the requirements of our target markets. The process of adding input raw materials (granulates) is conducted electronically, by a gravimetric method, which ensures proper distribution of the desired property over the entire surface of the material.

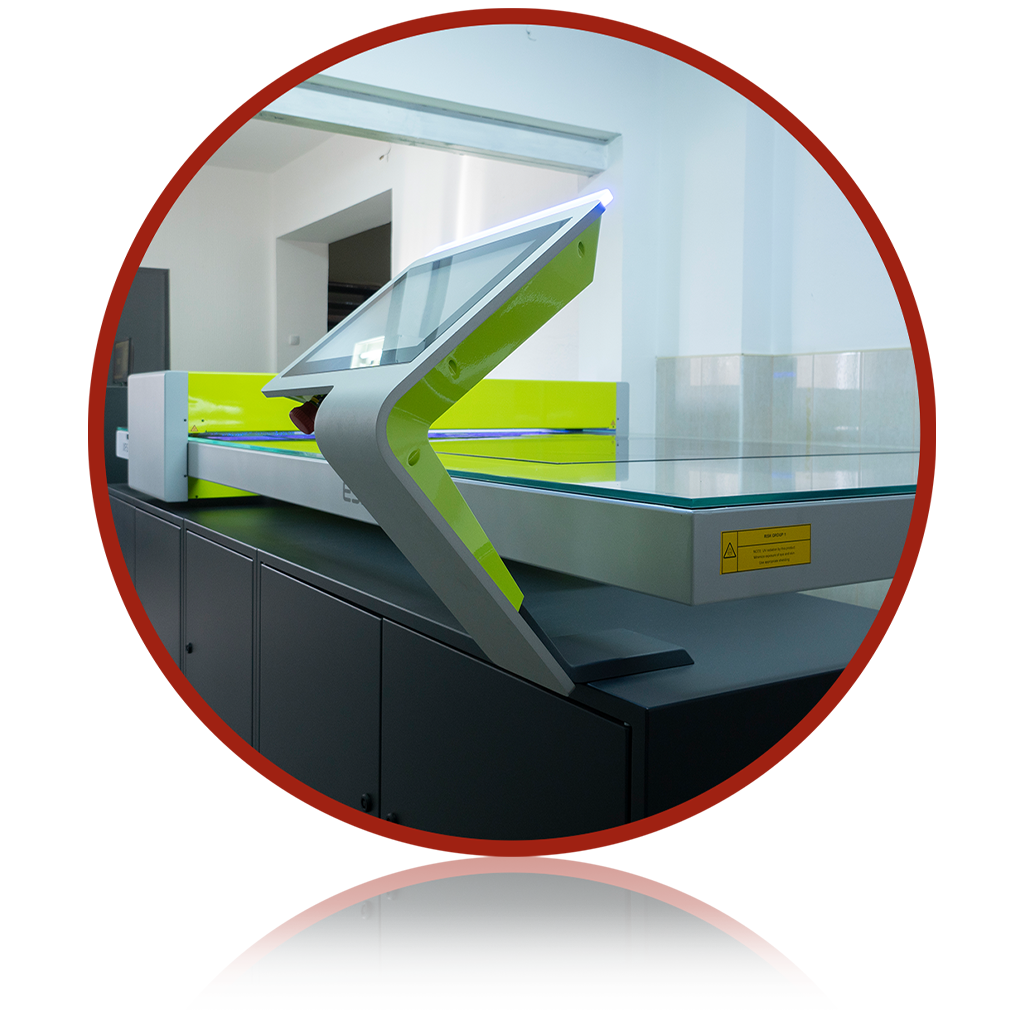

Prepress

The department is equipped with modern graphic technologies and tools

In co-operation with Esko Artwork, Comex prepress department is equipped with modern graphic technologies and tools. Today, Comex has the following Esko software in its graphic preparation department:

Automation engine software is a new standard for establishing an automated workflow in the prepress department with the ability to monitor each phase regardless of its duration. This software reduces the number of errors and improves efficiency.

Flexrip is Esko’s product intended for the preparation (raster) of files for the process of illumination on the printing board. Due to the wide range of choice of lineatures, raster point shapes, types of rasterization, Flexrip allows easy adjustment of the process of rasterization and preparation of materials for all printing techniques. Flexrip supports classic (AM), monet (FM) and hybrid (Samba) raster technology.

Flexproof is a response to the growing need for a test print in the packaging industry. In the modern way of communication between the printing industry and design agencies and marketing departments of customers, the test print represents the universal language of communication. A test print ensures error detection at the earliest stage of the workflow.

Artpro – Provides faster and more precise work on processing electronic files, provides the possibility of automatic trapping, the ability to combine different raster lineatures on the same separation as well as many other options that are not available in Adobe Illustrator. Artpro supports all industry standard file formats.

Desk Pack – epresents a plug-in for Adobe Photoshop and Adobe Illustrator. Desk Pack has two powerful tools, Flexo tools and Flexo Inks, which combined enable photo processing without losing quality or contrast of photography. The Flexo Inks tool provides a wide choice of combining existing colors in a specific design with the aim of obtaining a certain color shade.

HD flexo using HD laser head for engraving photopolymer plates, contributes to raising the quality of printing forms by increasing the output resolution and thereby raising the print quality. HD flexo provides an output resolution on the illuminator of 4000dpi instead of the current 2540dpi. High resolution will contribute to quality prints of fine raster audio transitions with exceptional sharpness. Flexo technology delivers raster prints below 3% due to a special way of rasterization with supported dots technology. In addition to the low raster values that the new technology has enabled in the press, there has also been an improvement in full-color printing thanks to the microcells technology that provides better transfer of color to the print media.

Laminating

We laminate materials with exceptional adhesive properties

In order to adequately produce and supply customers with quality duplex, triplex and quadruplex materials, Comex is now equipped with two machines for lamination of the materials by the leading company “Nordmeccanica”.

We laminate materials with exceptional adhesive properties between individual layers. Today, in Comex, we use several types of adhesives to fully respond to market demands regarding the quality of material lamination. The upcoming trend in the circular economy and the use of homogeneous materials in recyclable monoblock structures shifts the essence of the focus of the flexible packaging to which Comex is now ready to respond.

Postpress

Finishing of packaging materials

Postpress – the finishing of packaging materials takes an important place in our production chain. For our customers, we provide high quality finishing of materials with developed tracking and barcode identification system.

Today, Comex owns:

- Two slitters – cutters, one of which is automatic with double axles for fast replacement of rolls. Technical characteristics: maximum material width 1300 mm, maximum roll diameter 600 mm, maximum speed 550 m / min.

For us, confectioning is the conversion of packaging materials into the shape of bags in accordance with the requirements of customers for manual or automatic filling. The assortment of bags we produce includes bags for daily breads and toasts, bags for toilet paper, cotton buds, hygienic pads, bags for confectionery and snack industry, bags for packing granular and powdered products with the possibility of installing degassing valves, bags for frozen fruit, vegetables, semi-baked dough, as well as doypack bags with perforation for packing juices, mushrooms, pepperoni, olives, etc. - Machine for forming bags of different types: of mono, duplex and triplex structures

- Two machines for forming bags of LDPE, OPP, CPP materials

- Machines for forming doypack bags with or without perforation

Other equipment

The technological process of film production

In addition to equipment for printing, press preparation and co-extrusion of PE film, Comex has all the additional equipment that performs all other necessary operations in the technological process of production of printed packaging films, starting with computerized most advanced equipment with magnifying camera for mounting photopolymer plates, via automated equipment for washing anilox rollers, to the laboratory for the quality control of the input materials and quality control of the final product.